| Material Options | Specialty films, Specialty papers, Dupont Tyvek®, Foil laminations, Peelable or fusion versions |

|---|---|

| Sterilization Options | Radiation, Autoclave, ETO |

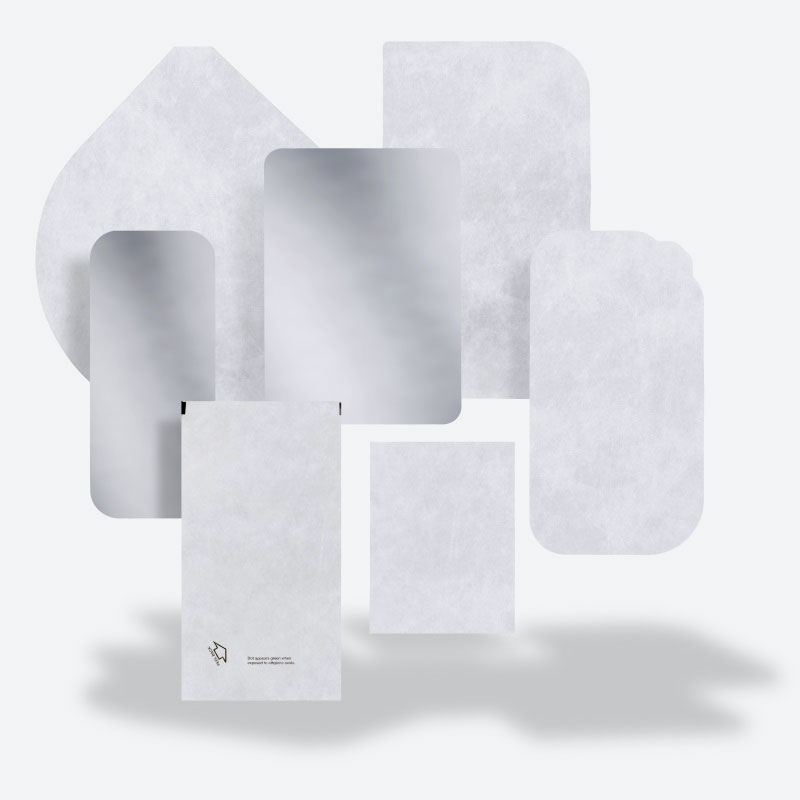

Lidstock

With decades of experience, Technipaq remains a trusted partner in providing flexible packaging that meets various requirements, including ISO 13485 compliance and sterilization compatibility. Our lidstock is high-quality, with custom design options, ideal for the medical, food, and pharmaceutical industries.

Customizable Lidstock Options

Technipaq understands that every client has unique requirements for packaging design. Our lidstock is available in a variety of options, allowing clients to customize their package by usability, branding, and durability.

Lidstock can be ordered in die-cut or rollstock, allowing for easy integration into automated systems and robotics used on the production line. Other custom options include:

- Printed Branding: Our lidstock can do up to 8-color flexographic printing, and allows for clear, high-resolution logos and labeling. This is valuable for product visibility and branding.

- Perforation and Barcoding: Perforated or barcoded lidstock offers easy access and traceability which is necessary for compliance.

- Peelable and Fusion (non-peelable) Seal Options: Peelable lidstock is needed for a secure, yet easy-to-access seal. This is usually helpful in personal and healthcare sterile presentation.

Lidstock Materials

- Specialty Films: Durable and flexible, these are ideal for high-performance medical packaging.

- Medical-Grade Tyvek®: Known for its strength and breathability, Tyvek® supports sterilization methods like ETO and radiation, ensuring compatibility with complex medical device packaging.

- Foil Laminations: These offer a barrier against moisture, oxygen, and light, crucial for both medical, pharma, and food packaging applications.

- Paper and Paper-Based Structures: These can be tailored to fit packaging needs that prioritize sustainability.

Supported Sterilization Methods for Lidstock

Our lidstock is engineered to withstand vigorous and various sterilization methods while maintaining product integrity. Whether its medical devices, food, or pharma, our products are designed to handle industry compliance.

- ETO (Ethylene Oxide): Common for medical devices and products that cannot withstand high temperatures.

- Radiation: Suitable for a wide range of medical packaging applications, ensuring sterility with minimal material impact.

- Autoclave: For high-temperature sterilization, our materials withstand extreme heat and pressure.

Advanced Coating Technologies with Techni-Coat

To expand our lidstock offerings, Technipaq has Techni-Coat and a new range of coated Tyvek®. These enhance durability, they work well on high-speed packaging lines, and they allow for additional printing and customization options.

Techni-Coat is significant for the medical device and pharma industry by providing enhanced surface strength and sterilization resilience for flexible packaging.

Technipaq offers a range of materials, including DuPont™ Tyvek®, foil laminations, and specialty films, all produced under ISO 9001/13485 standards. This ensures high-quality, compliant packaging that maintains the sterility and security of medical products.

Technipaq Lidstock Food, Pharma, and Medical Applications

Lidstock refers to the material used to seal trays for sterilized medical devices, pharmaceutical items, and other sensitive products.

Given that it protects sensitive items that must maintain their sterile integrity, lidstock material must be durable, able to withstand high-speed production lines, and compatible with different rigorous sterilization methods. Technipaq’s lidstock meets these requirements and is designed to complement complex packaging technology.

While medical packaging often takes center stage, food packaging and pharma also use lidstock. Foil laminations and barrier films protect against contaminants, keeping food and pharmaceutical products safe and fresh.

Frequently Asked Questions (FAQ)

What is the difference between peelable and fusion seals in lidstock?

Peelable seals provide an easily removable lid that maintains a secure seal until opened, ideal for medical device and personal care products. Fusion seals, on the other hand, offer permanent closure for products that don’t require resealing, ensuring high durability and protection.

How does Technipaq ensure compliance with industry standards?

Our lidstock solutions are manufactured under ISO 9001/13485 standards, with a focus on quality, reliability, and regulatory compliance, particularly for medical and healthcare packaging. This ensures our lidstock meets stringent industry regulations for safety and effectiveness.

Can Technipaq’s lidstock be used in thermoformed trays?

Yes, Technipaq offers lidstock compatible with thermoformed trays, providing a strong and durable seal for trays used in medical and pharma applications. Our lidding seals to many of the common thermoform materials like PETG, APET, PP, HDPE, and HIPS.

Why Choose Technipaq?

When it comes to packaging solutions for the medical, diagnostic, and pharmaceutical industries, Technipaq stands out as a trusted partner with over 40 years of expertise. We deliver custom solutions that ensure your products remain safe, sterile, and reliable.

Here’s why Technipaq is the right choice for your packaging needs:

- ISO 9001/13485 Standards Certified Manufacturing: Our commitment to quality is evident in our strict adherence to globally recognized standards, ensuring that every product meets the most rigorous regulations.

- Comprehensive Sterilization Compatibility: Technipaq’s packaging solutions are designed to withstand a variety of sterilization methods, including ETO, autoclave, and radiation, ensuring product sterility and safety every time.

- Innovative Materials and Design: Technipaq offers a range of materials, including DuPont™ Tyvek®, foil laminations, and specialty films, all produced under ISO 9001/13485 standards. This ensures high-quality, compliant packaging that maintains the sterility and security of medical products.

- Unmatched Expertise and Support: With over three decades of experience, we offer unparalleled knowledge and customer support. Our in-house testing and validation ensure that your packaging is built to perform under the most demanding conditions.

Choose Technipaq for packaging that prioritizes quality, innovation, and reliability – all backed by decades of industry experience. Ready to get started? Contact us today!